Symposium 2025

Tribology in Industry and Research

Interlocked Behavior – Where Tribology Meets Rheology

Seminar

Wednesday, 19 November 2025

Conference

Thursday, 20 November 2025

Motivation and Thematic Focus

Rheology studies the flow and deformation behavior of materials, while tribology deals with friction, wear and lubrication. Both disciplines overlap in numerous technical and biological applications in which two surfaces are in relative motion to each other through an intermediate medium – such as a lubricant – as in machines or human joints. In such lubricated tribosystems, the rheological behavior of the lubricant is decisive for the lubrication regime and therefore has a significant influence on friction and wear. Since shear, temperature and pressure are subjected to changes during operation, the rheological properties also change dynamically – with direct effects on tribological behavior. A deep understanding of these relationships is the key to targeted adaptations, whether in the development of new lubricants, in medical technology or in process-specific applications in the food sector. Rheological knowledge thus provides an essential basis for resource-saving, high-performance and durable solutions.

The ÖTG Symposium 2025 will focus on rheological and tribological strategies for modern production processes and product developments. The application of practical experience and current research outcomes opens up new potential for increasing efficiency, improving quality and designing sustainable tribological systems.

As part of the two-day program, you will have the opportunity to learn more about the importance of rheology in tribology from Prof. Milan Kracalik (JKU Linz) and Prof. Helen Wilson (University College London).

Expert presentations will inform you about the latest findings from both disciplines, and you will also have the opportunity to get to know the Anton Paar GmbH product portfolio directly on site.

Programme

Interviews

Die Tribologie – Ein Auslaufmodell oder ein Zukunftstreiber?

Patrick Beau, Optimol Instruments Prüftechnik GmbH

Click here to display content from videopress.com.

Forschungsfragen in der e-Mobilität

Katharina VÖLKEL, Lehrstuhl für Maschinenelemente (Prof. Stahl), TU München

Click here to display content from videopress.com.

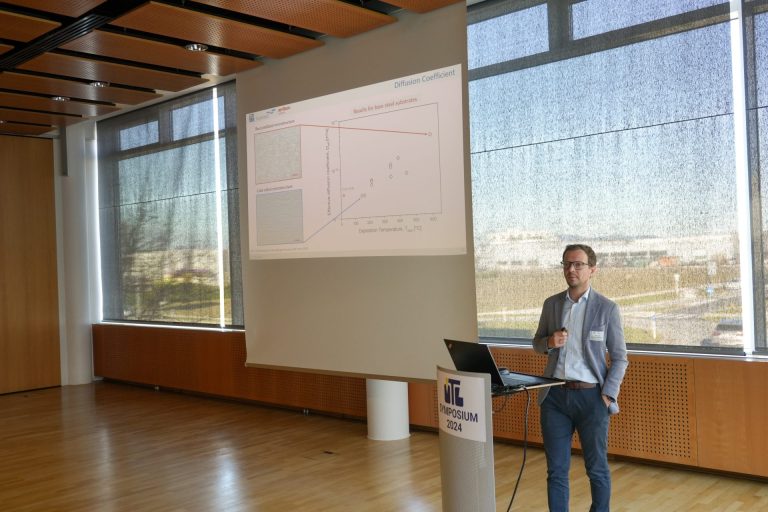

New measurement equipment at AC²T

Rainer Franz, AC2T research GmbH

Click here to display content from videopress.com.

Inspired by grease lubrication

Piet Lugt, SKF Research & Technology Development

Click here to display content from videopress.com.

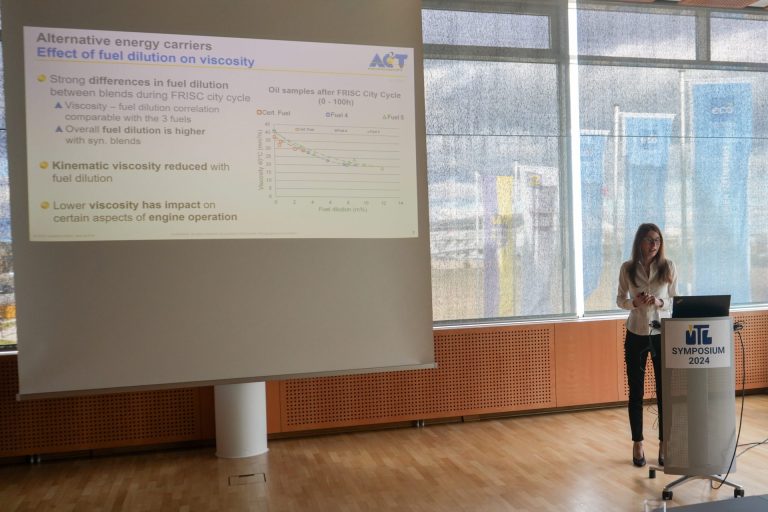

Research in alternative fuels

Marcella Frauscher, AC2T research GmbH

Click here to display content from videopress.com.

Interesting innovations in tribology

Kartik Pondicherry, Anton Paar GmbH

Click here to display content from videopress.com.

Der Einstieg in die Tribologie

Mirjam Bäse, Magna Powertrain GmbH & Co KG & Gesellschaft für Tribologie e.V.

Click here to display content from videopress.com.

Highlights des ÖTG-Symposiums 2024

Andras Vernes, AC2T research GmbH

Click here to display content from videopress.com.

Fotos

ÖTG Seminar

19 November 2025, 9:00-13:00

Rheology in Tribology

Piet Lugt, SKF Research & Technology Development, NL

Seminar goals

- General concepts of rheology of fluids

- Influence of rheological properties on tribological processes

- Applications in practice and research

- Modern methods for the characterization of rheological properties

(The seminar will be held in English.)

Seminar content at a glance

- Viscosity

- Influence of shear, temperature, pressure and time on viscosity

- Newtonian and non-Newtonian behavior

- Piezo-viscosity

- Viscoelasticity

- Thixotropy and rheopexy

- Examples from practice

- Lubricating oils and greases in machine elements

- Biological systems, e.g. joint lubricants

- Food industry, e.g. chocolate

- Cosmetics, e.g. creams

- Measurement of rheological properties – Rheometry

Lecturers

Anton Paar GmbH, AT

Pondicherry is a tribologist with a PhD in Tribology from the University of Leoben and a Master’s degree in Nanomaterials from the University of Ulm.

Since 2023, he has worked as a Global Product Manager for Tribology at Anton Paar GmbH in Graz. His areas of expertise include engine tribology, biotribology, polymers, and coatings.

Kartik PONDICHERRY

Anton Paar GmbH

Lecturers

JKU Linz, Institute of Polymer Science, AT

Prof. Kracalik received his PhD in 2006 from the Institute of Macromolecular Chemistry, Academy of Sciences of the Czech Republic. After a post-doctoral position at Montanuniversität Leoben and as development engineer at ISOVOLTAIC AG, he joined the Institute of Polymer Science at Joahnnes Kepler University Linz in 2014, where he leads the research group “Rheology”.

His research comprises processing and application of dispersive polymer systems (blends, composites and nanocomposites) and their characterization, nanotechnology in combination with material recycling of polymers as well as rheology of biological liquids (blood, synovial fluid, brain fluid).

Milan KRACALIK

JKU Linz

University College London, Department of Mathematics, UK

Prof. Wilson is a Professor of Applied Mathematics at University College London (UCL), Department of Mathematics.

Her research focuses on complex fluids, particularly non-Newtonian behavior such as viscoelastic fluids and particle suspensions. She investigates phenomena such as instabilities in elastic fluids and the interactions of particles in viscoelastic media.

Her work has applications in fields such as plastics processing, dental care products, and forensic science. Her pro-jects include the development of shear-thickening fluids for cryopreservation and the investigation of the rheology of toothpastes.

She is also known for her popular science lectures, including „Blood, Mud and Chocolate: Weird Fluids for Everyone“ and „Anyone for a mince pi?“.

She was the first woman to head UCL’s mathematics department (2018-2023).

Helen J. WILSON

University College London

ÖTG Conference

20 November 2025 | 9:00-16:30

Plenum

Sustainable raw materials – An opportunity for biolubricants?

Biolubricants, understood as “rapidly biodegradable” and “environmentally friendly” as well as provided with official environmental labels such as the EU ecolabel, are not self-selling products on the market despite years of sustainability debate. Why this?

This talk begins by looking at sustainable raw materials and their use in the lubricant sector. It also addresses the different properties of the various types of base oil: Rheology, polarity, additive solubility, etc. The second part deals with ecolabels and adequate standardization for biolubricants.

Rolf LUTHER

Chairman of the GfT (DE)

Rheology in the coating industry

This talk reports on how rheological behaviour of insulating coating materials affects all aspects of coating processes, mostly uniform application and control to achieving smooth surfaces and optimal performance. In the winding wire industry, solvent release, rheological properties, and the reactivity of the film formers determine the quality of the insulating coating.

Important factors include good processability, no running, prevention of sedimentation, and uniform layer formation. Application of varnish is carried out in up to 30 layers, followed by firing at over 500°C and return of excess varnish. Obviously, viscosity measurements are crucial for raw material inspection, release in semi-finished and finished products, thus for the selection of suitable operating parameters and final product quality.

Suljo CIRAK

ASTA Elektrodraht GmbH (AT)

The importance of multidisciplinarity in tribology – from fundamentals to applications

The talk will cover recent advances in modelling aspects of a variety of problems where the behaviour of tribological interfaces controls the performance of engineering systems.

It will start with an overview of the modelling tools developed to study interfacial and rheological phenomena across the scales, and will then move onto demonstrating how in-silico experiments can be used to shed light on physical, chemical and mechanical phenomena that affect frictional interactions and engineering performance in several applications in the energy sector, including electric vehicles (EVs) and triboelectric nanogenerators (TENGs), biomedical applications, consumer goods, and functionalized and hierarchical materials and surfaces.

Daniele DINI

Imperial College London (UK)

Lecture of the host - Anton Paar GmbH

Rheometry und tribometry

Kartik PONDICHERRY

Anton Paar GmbH

Invited talks

Blood rheology on modified rheometer surfaces

Fresh blood contains living cells with different extrinsic (size, shape) and intrinsic (deformability, aggregability) properties, which influence the bulk blood flow. The proteins and small molecules in plasma generate a very diverse embedment for these cells by their sizes from the Angstrom scale (enzymes, factors, hormones) to several tens of nanometers (lipoproteins, ferritin) and by their functions (adhesion, signaling, mechanical coupling). It is evident that such a material has the ability for structuring, adhesive layer formation and phase separation in flow, and cannot be handled as a simple liquid. We show new data on the correlation between plasma proteins, highlighting the importance of this cellular embedment for blood flow.

The fate of such complex physiological liquids in the vicinity of an interface plays a crucial role in multiple situations. Direct contact with blood for long times can produce thrombus formation. Highly hydrophilic surfaces are beneficial for cell adhesion and growth, whereas highly hydrophobic surfaces are considered useful for mobile prostheses (e.g. cardiac valves). Also, the surface morphology of the material in contact plays an important role for wetting ability with liquids. Shear moduli vary substantially if the substrate is changed from classical steel to hydrophobic polydimethylsiloxan-coated plates. The gap dependency and the timely evolution of shear elasticity show that the liquid is no longer homogenous.

This presentation also shows examples of how a substrate can modify the reading of torques by rheometry and raises the question about which substrate is the best for the testing of physiological fluids.

Ursula WINDBERGER

Medical University Vienna (AT)

The role of lubricants in view of decarbonization and energy transition – Ammonia as carbon-free energy carrier

Decarbonization is enabled by using alternative energy carriers like green electricity and carbon-free fuels such as hydrogen and ammonia, and each of these require appropriate lubricants.

This talk discusses the opportunities and challenges of ammonia, emphasizing its potential application as a future marine fuel. A methodology specifically designed to capture critical oil performance parameters is presented which revealed the impact of ammonia on stability behaviour, corrosion properties, deposit formation, and tribological properties of fresh and aged engine oil.

Ewald BADISCH

AC2T research (AT)

The formation of drops and sprays from complex liquids

The formation of drops and sprays by breakup of coherent liquid systems is influenced by deformation-induced stresses in the liquid. These stresses, which depend on the rate of fluid deformation, are given by the rheological constitutive equation of the liquid. Turning from Newtonian to Non-Newtonian liquid behavior, i.e. to complex liquids, jet or sheet breakup by Plateau-Rayleigh or Kelvin-Helmholtz instability may change dramatically, with impact on the size spectra of the drops formed. Experiments show that even small contents of a macromolecular polymeric substance in a liquid may strongly change the elongational viscosity of the liquid, while the shear viscosity may be left widely unaffected. Consequently, the influence of elongational material behavior is predominantly seen in ligament-mediated sprays.

The present talk discusses the material characterization relevant for complex liquid jet and sheet breakup. Linear jet and sheet stability analysis predicts the growth rate of unstable disturbances for linear viscoelastic liquid materials to be enhanced as compared to a corresponding Newtonian liquid with the same Ohnesorge number. The conflict with the experimental observation that macromolecular solutes in a liquid rather stabilize jets and sheets than destabilizing them is due to nonlinear effects. Experiments show that drop size spectra formed by breakup of jets of poly(ethylene-oxide) solutions in water-glycerol mixtures may be close to those predicted for Newtonian liquids. Mean drop sizes measured in complex liquid sprays from pre-filming atomizers are well predicted by functions of the liquid flow Weber number and an elongational Reynolds number, interpreted as a Deborah number.

Günter BRENN

TU Graz (AT)

Technical talks

Schmieröle & -fette

Dynamic surface roughness modeling for enhanced slider bearing wear prediction

This study explores dynamic surface roughness adjustment to optimize slider bearing designs. A multi-body simulation framework combines Greenwood/Tripp contact mechanics and Archard’s wear model to track both wear depth and evolving surface roughness parameters. Simulations under realistic engine conditions revealed a 46% reduction in predicted wear when running-in effects were included, along with improved oil film stability. Dynamic updates prevented overestimation of wear and supported more accurate bearing life predictions.

These insights enable better lubrication strategies and surface treatments, enhancing reliability in automotive and industrial applications where slider bearings are critical.

Stephen BEWSHER

AVL List GmbH (AT)

Exploiting fluid viscoelasticity for enhanced load capacity in 3D-lubricated contacts

Viscoelasticity in lubricants, arising from finite polymer relaxation time, can significantly enhance the load-carrying capacity of hydrodynamic contacts such as bearings, gears, and textured surfaces. Using reduced-order approaches – including a viscoelastic Reynolds formulation and first-order perturbation in the Deborah number (De, ratio of relaxation to flow time scale) – we analyse conical, textured, and finite-width channel geometries.

Results show that viscoelasticity improves film performance beyond Newtonian predictions, though alignment errors and spanwise effects introduce nonlinear trends, including saturation or reduction at high De. These findings highlight both opportunities and challenges in exploiting viscoelasticity for lubrication under extreme conditions.

“HPC_BIG_DATA_QUANTUM – National Center for HPC, Big Data and Quantum Computing – E13C22001000006 – Decreto MUR n. 1031 del 17/06/2022.”

Luca BIANCOFIORE

University of L’Aquila (IT)

From interface science to green synthesis of 2D materials: a pathway toward sustainable lubrication

MXenes are a class of two-dimensional materials known for their exceptional physical and chemical properties. Their technological advancement has been hindered by safety concerns, as conventional synthesis methods often involve hazardous chemicals.

In this work, I will present how we leveraged the principles of interface science, specifically surface nanobubbles, to enhance electrochemical synthesis and produce high-quality MXenes with significantly improved yield. I will discuss their surface terminations, which differ from classical MXenes. Furthermore, I will demonstrate the outstanding tribological performance of these materials discussed at the macro and nanoscale, establishing a new benchmark in the development of sustainable solid lubricants

Pierluigi BIOLOTTO

TU Wien (AT)

Werkstoffe & Oberflächen

Atomistic simulations to aid viscosity prediction and lubricant additive design

This contribution shows how atomistic simulations can help design better lubricants. We first explore how molecular motion at the nanoscale determines viscosity under different temperatures, pressures, and shear conditions, and how these data can be combined into a single, consistent description of fluid behavior. In the second part, we use chemical simulations to study antioxidant additives made from renewable sources such as lignin, focusing on their stability and ability to protect base oils from oxidation.

Together, these studies illustrate how molecular modeling can support the development of efficient and sustainable lubrication technologies.

Stefan J. EDER

AC2T research GmbH

TU Wien (AT)

Case study on oil condition monitoring – A practical and effective approach from sampling strategy to corrective actions

The relevance and benefits of oil condition monitoring in industrial environments are beyond question. Numerous service providers are available to support industrial companies in carrying out the various associated activities. Alternatively, certain aspects or the entire process can be managed internally by the company itself.

In this presentation, a targeted overall solution will be introduced using a practical example from an Austrian industrial company. The key feature is a software solution serving as the central interface for managing technical equipment, planning and recording measurement data, and suggesting corrective actions.

The specific implementation example within this industrial company illustrates the challenge of harmonizing smooth operational processes with the direct integration of analytical instruments.

Thomas FEISCHL

eralytics GmbH (AT)

Porous pathways to low friction: The tribology of MOFs

Metal-organic framework (MOF) nanoparticles emerge as effective lubrication additives. This study highlights the impressive solid lubrication performance of a Ti-based MOF, COK-47, which reduces friction by 8.5 times compared to AISI 304 steel. COK-47 consistently maintains a low coefficient of friction (0.1-0.2) across various materials, including Al2O3 and Si3N4, outperforming other MOFs and 2D materials.

The formation of a tribofilm through the hydrolysis of COK-47 in moisture is confirmed, with density functional theory indicating that water supports its decomposition. This research emphasizes the potential of MOF and water-assisted lubrication in advancing tribology.

Carsten GACHOT

TU Wien (AT)

Komponenten & Systeme

The development and characterization of automotive brake pad friction materials, focusing on incorporating novel 2D materials as solid lubricants

This study evaluates titanium-based MXene (Ti₃C₂Tₓ) as a superior solid lubricant for brake pads, comparing it to conventional molybdenum disulfide (MoS₂) and a hybrid of both. Incorporated into a fixed matrix, the composites were analyzed for thermal, mechanical, and tribological properties. Pin-on-disk testing against grey cast iron revealed that Ti₃C₂Tₓ significantly outperforms MoS₂.

The hybrid formulation reduced the specific wear rate by 16.5%, while the Ti₃C₂Tₓ-only composite achieved a substantial 48.5% reduction in wear compared to the MoS₂-based material, demonstrating MXene’s exceptional potential for enhancing brake pad durability and performance.

Eslam MAHMOUD

TU Wien (AT)

Innovative 2D materials for reducing friction: ab initio simulations coupled with experiments

In the quest for efficient solid lubrication under extreme conditions, two-dimensional materials such as graphene and MoS2 have emerged as powerful alternatives to conventional liquid lubricants. The exploration of novel 2D compounds represents an expanding frontier in tribology, demanding a multidisciplinary approach that bridges chemistry, physics, and materials engineering.

This talk will highlight recent advances in understanding the tribological behavior of next-generation 2D materials through the combined use of density functional theory simulations and experiments. Particular attention will be devoted to MXenes (Ti3C2Tx), transition metal carbochalcogenides (Nb2CS2), and 2D metal organic frameworks, as promising solid lubricant candidates of the future.

Edoardo MARQUIS

TU Wien (AT)

Pin-on-disc tests for biomedical materials and medical devices

Friction plays a crucial role in biomedical applications, from knee implants that require low friction for smooth movements, to implants where controlled friction at the implant bone interface aids osseointegration, and catheters that must slide easily into blood vessels or urethra. Although simple, the pin-on-disc method remains essential for providing reliable and meaningful data when tribological conditions are known or well estimated.

In this contribution we present three case studies: frictional analysis of hip implants against bone, evaluation of protective coatings on knee implants, and comparison of coated catheters. These results demonstrate the method’s versatility of simulating realistic biomedical conditions.

Jiri NOHAVA

Anton Paar TriTec SA (CH)

Investigation of solid self-lubrication mechanisms of B2O3 in TiB2±z and WB2±z based thin films

Transition metal borides such as TiB2±x and WB2±x are promising materials for protective coatings, because they combine high hardness with self-lubricating properties. At high temperatures, they form a thin B2O3 layer that helps reduce friction. Super-stoichiometric TiB2.9 shows lower friction than TiB1.5 because the extra boron produces more lubricating oxide. Similarly, α-WB2±z coatings also exhibit self-lubrication properties.

However, they tend to stabilize in the sub-stoichiometric form, resulting in reduced amounts of boron available for oxidation. The tribological data are further correlated with XPS, XRD, and TEM analyses, offering new insights into the lubrication mechanisms of boron oxide in thin films

Daniel PÖLZLBERGER

TU Wien (AT)

Under (hydrodynamic) pressure – A novel test methodology to compare the performance of different textures under varying conditions

A numerical approach is used to identify optimal parameters for single- and multi-dimple textured convergent oil film gaps that can be practically manufactured by milling. Furthermore, a novel test method is developed on an Anton Paar MCR rheometer to evaluate these textures in full-film lubrication, varying rotational speed, temperature, and minimal oil film gap height.

Results show that single-dimple textures achieve the highest load-carrying capacity. At 23°C, both textures reduce drag compared to untextured gaps, though this benefit diminishes with rising temperature. Nevertheless, the load-carrying capacity of textured surfaces consistently exceeds that of untextured oil film gaps.

Raphael SCHARF

Montanuniversität Leoben (AT)

Experimental investigation of tire wear particle sizes

The new EURO 7 emission standard includes, for the first time, tire wear. Previous research has given relatively little attention to the distribution of tire wear particle sizes; however, this is important in determining their environmental impact.

Therefore, this study employed a mini traction machine to simulate real-world tire abrasion, using a ball made of tire material, and an asphalt disc composed of gravel and bitumen. Various tests were conducted with different normal loads, slip ratios, and velocities, and the generated particles were analyzed with a laser diffractometer, classifying them by size.

Alexander SCHMIEDHOFER

TU Wien (AT)

Impedance measurement in bearings for lubricant testing and condition monitoring

The lubrication condition is a determining factor for the lifetime of bearings. By detecting the electrical potential between bearing and shaft, the lubrication condition can be monitored.

in this talk, we introduce a method that applies a high frequency impedance signal. In various applications it could be shown that valuable information for lubricant development and condition monitoring is achieved:

- Stribeck curve in real application

- Pitting development from initiation to particle

- Development of surface layers, protective reaction layers or varnish

- Development of oil ageing: particle generation, contamination

- Forces in bearings in real application

Christoph WINCIERZ

HCP Sense GmbH (DE)

Organisational Committee

Priv.-Doz. Dipl.-Ing Dr.

Nicole Dörr

ÖTG

Ernst-Dieter Janotka

ÖTG

Univ.-Prof. Dr.-Ing.

Carsten Gachot

ÖTG & TU Wien

Institute of Engineering Design and Product Development

Priv.-Doz. Dipl.-Ing. Dr.

Bernhard Scheichl, Hon. Assoc. Prof.

TU Wien

Institute of Fluid Mechanics and Heat Transfer

Dr.

Timea Erzsebet Varadi, MSc.

Floridsdorf Clinic

Medical Physics Unit

Venue, travel & accommodation

Anton Paar GmbH

Anton-Paar-Straße 20, 8054 Graz, Austria

Information regarding the venue, travel and accommodation can be found here.

Click here to display content from maps.google.com.

Call for Abstracts

Please send your name, organization, title and an abstract of max. 100 words of your contribution to office@oetg.at .

As soon as your contribution has been accepted, please send us a high-resolution portrait photo and register for the symposium.

Call for Posters

Please send your name, organization, title and an abstract of max. 100 words of your poster to office@oetg.at .

As soon as your poster has been accepted, please send us a high-resolution portrait photo and register for the symposium.

Your poster will be presented in the break area.

Exhibition stand

10At the same time as the Conference, a trade exhibition will be organized in the large break area.

Please send your name, organization and information of your stand (e.g. electricity, monitor, table) to office@oetg.at .

Registration

The participation fee includes the conference materials (online), the seminar, the conference and refreshments during breaks and lunch. Prices exclude VAT.

Registration is closed. If you still want to participate please contact us via office@oetg.at.

Contact

Dr. Nicole Dörr

President

Ernst-Dieter Janotka

Secretary General

If you have any questions about the ÖTG Symposium 2025, please feel free to contact us.

Sponsors