Review - Symposium 2024

Symposium 2024

Tribologie in Industry and Research

Tribology as Key Enabler

Seminar & Symposium

Wednesday, 20. November 2024

Thursday, 21. November 2024

Technologie- und Forschungszentrum Wiener Neustadt

Viktor-Kaplan-Straße 2, 2700 Wiener Neustadt, Austria

Motivation and Thematic Focus

Climatic, economic and technological change is both an opportunity and a challenge for tribology. The energy and mobility transition are based not only on alternative technologies to the combustion engine and fuels, but also on energy efficiency, which has long been optimised by tribological solutions that reduce the coefficient of friction. Wear protection is another of tribology’s very own fields of activity, which is realised by customised surfaces, in particular coatings, and thus contributes to the conservation of resources. Tribology is therefore one indispensable key enabler in achieving the ambitious goals for a carbon-neutral future and a circular economy. High-speed components, as we know them from electromobility, and systems with hydrogen are only possible through design with suitable geometries, materials and lubricants.

The ÖTG Symposium 2024 highlights tribological solutions for production processes and product applications and the emerging potential. The findings thanks to scientific methods as well as sophisticated and specialised research approaches demonstrate tribology as key enabler in the energy and mobility transition and the circular economy.

During the 2-day program, you have the opportunity to learn about grease lubrication in roller bearings from Prof. Piet Lugt, SKF, be informed via technical presentations about recent findings in tribology and visit the research facilities of AC2T research GmbH (AC²T).

Interviews

Die Tribologie – Ein Auslaufmodell oder ein Zukunftstreiber?

Patrick Beau, Optimol Instruments Prüftechnik GmbH

Click here to display content from videopress.com.

Forschungsfragen in der e-Mobilität

Katharina VÖLKEL, Lehrstuhl für Maschinenelemente (Prof. Stahl), TU München

Click here to display content from videopress.com.

New measurement equipment at AC²T

Rainer Franz, AC2T research GmbH

Click here to display content from videopress.com.

Inspired by grease lubrication

Piet Lugt, SKF Research & Technology Development

Click here to display content from videopress.com.

Research in alternative fuels

Marcella Frauscher, AC2T research GmbH

Click here to display content from videopress.com.

Interesting innovations in tribology

Kartik Pondicherry, Anton Paar GmbH

Click here to display content from videopress.com.

Der Einstieg in die Tribologie

Mirjam Bäse, Magna Powertrain GmbH & Co KG & Gesellschaft für Tribologie e.V.

Click here to display content from videopress.com.

Highlights des ÖTG-Symposiums 2024

Andras Vernes, AC2T research GmbH

Click here to display content from videopress.com.

Photos

ÖTG Seminar

Technologie- und Forschungszentrum tfz, Wiener Neustadt, 20. November 2024, 9:00-12:00

- Lubrication mechanisms

- Grease rheology

- Grease degradation (mechanical and chemical)

- Oil separation (bleed)

- Sustainability and grease lubrication

- Grease life, traffic light concept and relubrication intervals

- Fretting and false brinelling

- Grease types (thickener, base oils, additives)

- Grease selection

- Grease specifications and testing

- Lubrication systems and pumpability

Biography

Piet Lugt studied mechanical engineering and tribology at the University of Twente in The Netherlands (MSc. in 1988, PhD. in 1992).

He worked at the Technical University of Delft until 1995 when he joined SKF Research where he has fulfilled several positions in Tribology and Lubrication. Presently, he is Senior Scientist at SKF Research and Technology Development. Piet Lugt is also Full Professor and Scientific Lead of the SKF University Technology Centre for Grease Lubrication at the University of Twente.

He is a fellow of the STLE, has been a part-time Professor at Luleå Technical University, Sweden, from 2005-2008 and is (part-time) full professor at the University of Twente since 2011.

Piet Lugt has written the book “Grease Lubrication in Rolling Bearings”.

Piet Lugt

SKF Research & Technology Development

ÖTG Symposium

Technologie- und Forschungszentrum tfz, Wiener Neustadt, 21. November 2024, 9:00-16:30

Plenum

Recent developments in understanding grease lubrication in rolling bearings

During the last decade great progress has been made in understanding the lubrication mechanisms in grease lubricated bearings. I will give an overview of the model development in this area such as on the effect of churning, grease bleed, filling, mechanical degradation and oxidation on grease life. For ball bearings, the concept of minimum life is introduced. The significance of understanding rheology and grease flow will be discussed. The latest models to predict film thickness will be shown. Grease specifications contain parameters such as consistency, bleed, mechanical stability, oxidation, R0F/FE9 testing etc. This presentation will also show how these could be refined in the future.

Piet Lugt

SKF Research & Technology Development

Research approaches for sustainable drivetrains using the example of wet friction clutches

Energy not lost to friction does not need to be generated. This drives activities aiming the reduction of load dependent and load independent losses to a new level. Moreover, the most sustainable component is the one that is not manufactured. Durability, including the potential for a second life, is coming into focus. This contribution highlights research approaches in the context of sustainability using the example of wet friction clutches.

Katharina Völkel

Chair of Machine Elements (Prof. Stahl), TU München

Surface engineering in emerging hydrogen technologies

The current transition from fossil fuels to green and environmentally friendly energy supplies focusing on hydrogen technologies is devoted to diverse challenges, primarily material science-related problems. The topmost micrometer of components used in hydrogen technologies faces specific deterioration mechanisms related to hydrogen embrittlement, corrosion phenomena, or permeation processes. Therefore, this talk gives an overview of the predominant challenges in designing state-of-the-art thin film materials. The focus lies on physical vapor deposition-based synthesis techniques and hydrogen-specific characterization methods.

Helmut Riedl-Tragenreif

Institute of Materials Science and Technology, TU Wien

Lubricating oils & greases

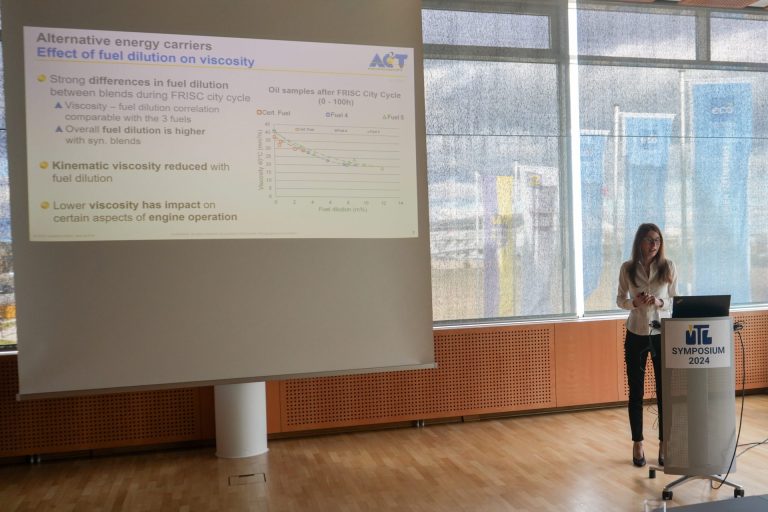

Supporting mobility transition – Tribology of alternative energy carriers

Besides e-mobility, fuels with zero-carbon emissions are necessary to achieve mobility transition. Hydrogen and ammonia are considered as sustainable fuels. Their impact on lubricants and engine components, and consequently friction and wear are still largely unknown. The Lab-to-Field approach is presented which combines techniques such as artificial oil ageing, tribometry and mass spectrometry to elaborate the influence of alternative energy carriers on lubricant degradation, lubricant condition, and consequently its effect on lubrication performance.

Marcella Frauscher

AC2T research GmbH

On the importance of tribology for industry and science

The benefits of our science of tribology for the environment, society and the economy have long been known and well described. The talk will therefore address the question of which levers are conceivable for utilizing these benefits “in the past, today and in the future”. Among other aspects, examples will be discussed: What valid characteristics can we already provide today, what new challenges are there and where is the added value actually generated by theoretical tribology and experimental tribometry.

Patrick Beau

Optimol Instruments Prüftechnik GmbH

The impact of grease service life on lifecycle costs and sustainability of axle box rolling bearings in rolling stock

The railway and its economic operation plays a crucial role in the effort to make mobility more sustainable. In axle box rolling bearings for rolling stock, the lubricant typically represents the limiting factor for the service life of the bearing. The resulting necessity to regularly refurbish bearings significantly contributes to the lifecycle costs of a rail vehicle. For an economically optimized as well as sustainable operation of rolling stock, a continuous elongation of the maintenance interval of axle box rolling bearings is pursued. It will be presented how the maintenance intervals of axle box rolling bearings have developed in recent years and with which mainly empirical approach this has been achieved. Based on this, an outlook will be given as to which developments and data-based approaches this process will be continued and accelerated.

Thomas Macheiner

Siemens Mobility Austria GmbH

Materials & surfaces

Accelerating material design using pre-trained large language models

Environmental pressures and performance gaps necessitate the development of new materials for modern applications. High Entropy Alloys (HEAs) show great potential but are complex, limiting the effectiveness of traditional phase diagrams, first-principle simulations, and machine learning approaches. The proposed strategy leverages Large Language Models (LLMs) and pre-trained transformers to maximize accuracy with small datasets. This approach facilitates the design of materials with tailored properties, addressing some of today’s challenges in surface engineering.

Spyros Kamnis

Castolin Eutectic UK

On the assessment of wear properties of coatings for casting surfaces

Low-load reciprocating friction and wear tests were performed on different types and thicknesses of coatings used for durable molds. An attempt to evaluate the time of the coating breakthrough was made through changes in electrical resistance, friction signal, wear signal, and 3D data of the wear scar. Even when combining the results, the determination of the coating wear resistance remains challenging.

Igor Velkavrh

V-Research GmbH

Sustainable Wear Protection – A material scientific and life cycle assessment approach

High-temperature wear protection materials mostly rely on Co, Cr, and Ni, which cause significant environmental impact and are also critical raw materials with limited supply. A sustainable alternative are reinforced iron aluminides, using B, C or recycled cermets, offering comparable or superior mechanical properties and wear resistance up to 700°C. These material solutions can extend service life, lowering maintenance costs and downtimes at reduced environmental impact, where life cycle assessment pointed out up to 70% reduction compared to Ni- and Co-based alloys.

Harald Rojacz

AC2T research GmbH

Components & systems

Performance loss of e-drive lubricants caused by water and iron particle contamination in wet clutches

Knowledge of the gear oil condition is a key aspect in electric drivetrains to prevent premature failure of individual components or entire subsystems due to induced frictional vibrations (shudder). In this study, the effects of water and iron particle contamination on the degradation of e-gear oils are experimentally investigated by evaluating the friction behavior of wet multi-plate clutches. The results are discussed using a method for the quantitative determination of this damage in an application-related environment.

Johannes Wirkner

Lehrstuhl für Maschinenelemente (Prof. Stahl), TU München

Triboacoustic pin: in-situ measurement of the film thickness in lubricated contacts

The development of lubricants and lubricated tribosystems requires extensive tribological tests, where the formed lubricant film is decisive regarding load-bearing capacity, energy efficiency and service life. The innovative triboacoustic pin allows the in-situ detection of the lubricant film thickness and provides valuable additional information about the performance of a lubricant and for the targeted optimization of lubricated tribosystems.

Fabio Tatzgern

AC2T research GmbH

Modelling techniques for the digitalisation of tribometers using the example of a two-disc tribometer

The investigation of tribological systems on test stands (tribometers) is challenging due to the complex interactions between machine dynamics, contact forces and wear. Extensive simulation methods are crucial for reproducible scientific tests and detailed insights into friction and wear mechanisms. In this talk, a modelling approach will be presented that aims to provide the digital twin of a tribometer. One focus is put on the generation of a finite element model of a two-disc tribometer. This model allows an initial assessment of the effects of machine vibrations on the tribological contact and forms the basis for further modelling steps.

Gottfried Brunbauer

AC2T research GmbH

Sponsors